The project investigated the emergence and development of balance scales with variable arm-length of which the so-called Roman steelyard is the most well-known.

Research

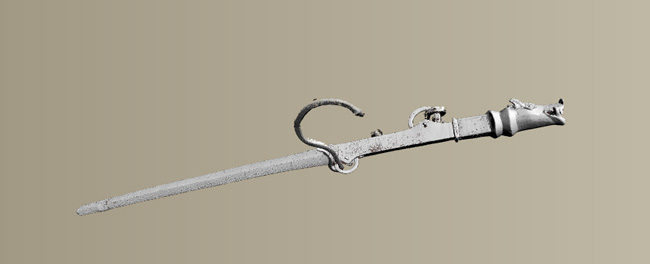

Image above: Roman steelyard circa 79 CE, found in Pompeii |Source: Naples, National Archaeological Museum. Inv. No. 5569 | Photo: Jochen Büttner, with permission

The research within this project set out from analysis of the extant material evidence. Based on this the members of this project modelled the innovation process of the steelyard and interpret it by reconstructing the historical circumstances under which it arose. They inquire into the different forms of knowledge related to these weighing instruments. The central effort in this regard concerned the reconstruction of the design and fabrication knowledge which mediated the production of balance scales with variable arm-length at different times and places in the ancient world. The project aimed to elucidate how different knowledge resources have shaped the innovation process and what knowledge was generated by this process.

The research was organised into the four sub-projects, Foundations, Knowledge, Innovation and Textual Record.

Foundations

Research starts with a comprehensive survey of a broad corpus of material artefacts, previously only inadequately studied and indeed insufficiently identified. In a pioneering attempt, Norbert Franken presented in 1993 a catalogue listing about 250 ancient steelyards. When the project started in 2012 this still represented the most comprehensive inventory of ancient steelyards. As part of and precondition for the research within this project, it was possible to expand this corpus to include (as of the end of 2016) more than 1000 steelyards, from Antiquity, late Antiquity and the early Byzantine period. In order to identify these objects among others nationwide campaigns have been conducted in which all institutions in a given country have been contacted in which steelyards could potentially be preserved.

Results

The catalogue which has thus been established has been published in two different online formats: as the collection “Ancient steelyards” in the Edition Topoi (http://repository.edition-topoi.org/collection/BSYP) and as the online database “Steelyard Navigator”. The collection “Ancient steelyards” currently comprises about 200 objects. Publication is cumulative and will continue to add objects on a biannual basis. All information provided is authored, can stably be referenced by DOIs and independently cited as well as reused and distributed under a Creativ Commons licence. In the “Steelyard Navigator” all objects currently identified by the project are represented with an indication of their respective editorial status. Material of the Navigator is freely available for scholarly purpose (for inquiries, please email: jochen.buettner@topoi.org).

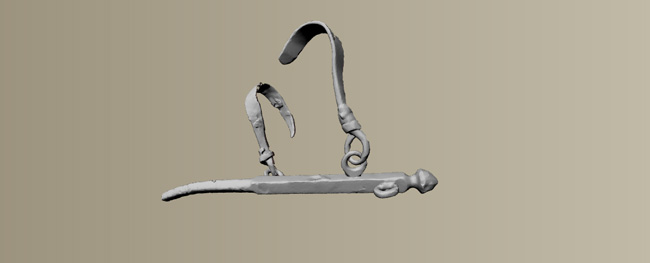

More than a quarter of the objects identified have been analysed in museums all over the world. All information secured in these campaigns is being made accessible. This includes in particular 3-d scan data of the objects as well as our analysis thereof.

As a direct result of our engagement with the material artefacts a number of articles presenting selected groups of objects are currently in preparation, or have been completed and are being submitted for publication.

During our campaigns in museums it was realised that a particular type of balance, namely equal-arm balances, equipped with an additional movable counterpoise, were much more commonly used in the Roman period than has been assumed. In the literature balances of this type have occasionally been mentioned, but have not been systematically studied. Sample checks of the equal-arm Roman balances preserved in various museums, have revealed that the addition of a counterpoise to such balances was the rule rather than the exception. Thorough analysis of this type of balance has lead us to the hypothesis that the Roman steelyard developed from this hybrid type rather than, as commonly assumed, from the so called Bismar, which was introduced in the 5th century BCE. This hypothesis will be corroborated in Gleicharmige Waagen mit zusätzlichem Laufgewicht by Christian Golücke and Jochen Büttner.

Knowledge

Central to the sub-project “knowledge” is the reconstruction of the knowledge upon which the design and the fabrication of ancient steelyards were based. The members of the project seeked on explanations of how this knowledge emerged, how it was transmitted and diffused and how it developed over time. They approach these questions starting from an analysis of the concrete objects.

Results

It could thus be shown that the knowledge required to successfully design and fabricate a fully functional steelyard is much more intricate than may superficially be supposed. In order to manufacture a steelyard suitable for weighing purposes, a number of non-trivial boundary conditions have to be satisfied. Many of the problems that have to be solved in fabricating a steelyard are related to the dead weight of the instrument, i.e. that the instrument has a weight, which, opposed to the case of the equal-arm balance, influences its equilibrium.

The makers of Roman steelyards were able to solve the ensuing problems in a consistent, remarkably ideal fashion. The preserved steelyards obey certain general principles with regard to their design, i.e. they show repeating complicated patterns in the relations between the relevant design parameters. These regularities can be straightforwardly interpreted as the result of recurrent similar actions in their production, which themselves are the external consequence of the sequential execution of procedural rules.

Based on 3-d scans of steelyards taken in museums all over the world, regularity patterns, mediating the design of different types of ancient steelyards, have been identified. The regularities in turn have allowed us to reconstruct the procedural rules applied in production. Among the rules are such that embrace variations contingent on prior choices. As a consequence, the relationship between different objects, produced according to the same set of rules, is not immediately apparent. Thus, whereas it is conceivable that individual steelyards could have been produced by copying, we have argued that the fabrication of a broad range of application specific steelyards as it is evidenced in the Roman Empire at remote distances and time intervals, can only have been possible if these rules were explicated and diffused in the context of production.

The investigations have thus revealed that the production of Roman steelyards was a matter of highly standardized design. This standardization mattered, as it allowed to consistently produce balances capable of fulfilling their intended functions. With the reconstruction of the design rules we thus have disclosed the specific technical knowledge intrinsic to the construction of the balances.

Next to design knowledge we have investigated concrete crafts and fabrication knowledge as it manifests itself in the way in which different components of the artefacts examined are realised. Why for instance were certain materials preferred over others? A choice of raw material can be stipulated by the intended function, such as for instance when stability considerations dictate selection. It can, however, also be influenced by external factors such as, for instance, when the availability or absence of required crafts knowledge at a given time in a certain region dictates the selection of the material to be used.

In reconstructing this type of knowledge we again start from the concrete objects. In cooperation with Frank Willer, metal samples have thus, for instance, been taken from the Roman steelyards preserved in the LVR-Landes Museum Bonn. These samples are being currently subjected to metal analysis. Together with Roland Schwab (CEZ für Archäometrie in Mannheim) the results will be interpreted in order to inquire into the metallurgic knowledge resorted to in the fabrication of steelyards. The project moreover solicit the expertise of smiths and casters to find explanations why the realised solutions were historically chosen from among a range of functionally equivalent alternatives.

The reconstruction of the crafts and fabrication knowledge ties in closely with the sub-project Innovation. The project hs indeed shown that the transitions between different technical types that occurred in the development of the steelyards were more often than not triggered by changes regarding this type of knowledge. A first synopsis of the investigation into the relation between knowledge and innovation is published in:

Jochen Büttner and Jürgen Renn, “The Early History of Weighing Technology from the Perspective of a Theory of Innovation” in: Space and Knowledge. Topoi Research Group Articles, eTopoi. Journal for Ancient Studies, Special Volume 6 (2016).

Innovation

The sub-project “Innovation” investigates the technical innovation process the Roman steelyard underwent in the first one thousand years after its initial inception, presumably in the first century BCE. Within the project technical types have been identified and their coexistence and succession have been reconstructed diachronically and synchronically. Explanations for the historical developmental sequence thus reconstructed have been advanced.

As a technical type, the project defines a constellation of abstract technical components together with their concrete realisations. An abstract component is identified by the mechanical function it serves in the overall arrangement of the object studied. An example is the flexible connector, a non form-locked element, capable of transmitting tensile forces and of retaining structural stability under the forces expected to occur in use. An abstract component can as a rule be concretely realised in different ways. A flexible connector, for instance, can be realised by a rope or likewise by a chain.

Which mechanical functions a component serves as part of a technical arrangement needs to be determined by analysis which includes the reconstruction of function and use of the overall arrangement. In the case of the steelyard for instance the load-chains not only served to attach, either by means of hooks or else a scale pan, the load to be weighed. At the same time they served as counterweight by means of which the steelyard was appropriately evened out. With regard to this function, ropes substantially differ from chains, which operate in the ancient steelyards. In the course of development, the connector component used for the load hanging was indeed further differentiated when an additional load-side weight was introduced, defining a technical type that has been referred to as type Walbrook.

Technical types can be different with regard to the constellation of abstract technical components they represent. Much more common however, is the case in which different types are characterised by identical constellations of components which differ with regard to the way in which the components are concretely realised.

Results

Based on this understanding of technical types, the typology of the more than one thousand ancient steelyards identified by the project has been developed. This forms the basis of our investigation into the technical innovation process of the steelyard. On the one hand, archaeological methods are applied to identify the spacial and temporal distribution of the types recognised. On the other hand, explanations are sought that can account for the transitions between the different types. Both approaches mutually bolster each other. The reconstruction of the historical sequence serves as a heuristic in the search for explanations. Explanations which favour certain developmental trajectories over others can help close gaps in the reconstruction of historical processes.

In this way a historical sequence of technical types is being reconstructed. It has thus been shown that the innovation process is characterised by a succession of technical types distinguished by stable configurations of groups of functionally dependent components. As it has turned out, functional benefits and/or advantages with regard to production economy can be held accountable for the transitions between types that occurred historically. Favourable production economy thereby is not to be understood in a modern sense as price-cutting but in a more general sense as the characteristic of a given fabrication method to allow the production of a comparable product with less effort, given the means available, in the respective historical situation.

The technical innovation process of the steelyard whose underlying mechanisms have thus been identified by the sub-project carries on for about one thousand years. It is among the most striking facts revealed by the project that around the ninth century CE this process resulted in a technical type that was apparently so robust against changes in the contexts of production and use, that essentially steelyards remain to be produced to the present day according to this technical type.

Textual record

Ancient sources on steelyards have yet to receive sustained consideration. The sub-project “Textual record” has investigated the terminology that was used to describe different types of weighing scales.

It could thus be shown that the Latin term statera was not regularly associated with the steelyard (unequal-arm balance), notwithstanding its explicit description by Vitruvius as such. Instead, it was used to refer to small or precise scales (that derive their name from the unit of stater), as opposed to trutina, a set of scales designed to weigh greater loads. The use of this term is therefore indicative of the initially relatively small weighing-range of steelyards in the early imperial period. Since the second century CE at the latest, the term charistio(n) (associated with an obscure instrument allegedly designed by Archimedes) also came to be used to refer to a steelyard not only in Greek but also in Latin. A recently published inscription, found on a late-antique steelyard, verifies this. The term campana/kampanon is attested since Late Antiquity and often associated with a relatively large weighing-range. Its attestations in the sources seem to coincide with the archaeological evidence for large, sophisticated steelyards in Late Antiquity. The results of the project are published in: